Spirovent® and Spirotrap® separators are installed in hundreds of hospital and medical centers throughout North America.

Related Work

American Museum of Natural History - New York, NY

Custom fabricated 30" high velocity air eliminator installed to solve noise problems in the existing system.Residential Gallery

Spirovent® remains the world class standard that others attempt to reach. Often copied but never equaled.Commercial Gallery

Spirovent® is now the basis of design in many specifications by the top consulting engineering firms for new construction.Industrial Gallery

Spirovents have been installed in many new and existing industrial HVAC systems.Related Work

Penn State University - State College, PA

Penn State is one of our largest university customers with more than 90 units installed across campus.University of Missouri - Columbia, MO

The University of Missouri, Columbia is home to the second of the world's largest Spirovent® combination air eliminator and dirt separator.Waukesha Memorial Hospital

The Spirovent was selected and installed to prevent dirt and sediment in the existing system from reaching a new addition and improvements went even beyond that.International ALERT Academy, Big Sandy, TX

“I have not had to vent a coil in the three months since

Related Work

Cottey College - Nevada, MO

From the President's house to the power plant, to almost all buildings on campus, Spirovents have contributed to efficient system performance across the campus.University of Nebraska - Lincoln, NE

With close to one hundred Spirovents installed, The University of Nebraska at Lincoln is one of our largest higher-ed customers.Industrial Gallery

Spirovents have been installed in many new and existing industrial HVAC systems.Boehringer Ingelheim - St. Joseph, MO

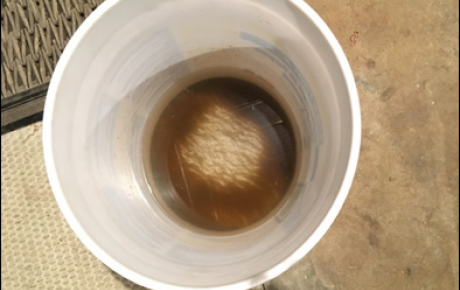

Custom 20" high velocity dirt and sediment separator with removable top head for access to Spirotube® element bundle.Related Work

South Point Hotel, Casino & Spa - Las Vegas, NV

Custom fabricated 24" high velocity combination air eliminator / dirt separator for the hot water system and custom fabricated 30" high velocity air / dirt for chilled water.Purdue University - West Lafayette, IN

Spirovent exceeds expectations and leads the University to purchase and install (32) additional units at the village.Residential Gallery

Spirovent® remains the world class standard that others attempt to reach. Often copied but never equaled.Boehringer Ingelheim - St. Joseph, MO

Custom 20" high velocity dirt and sediment separator with removable top head for access to Spirotube® element bundle.Related Work

University of Missouri - Columbia, MO

The University of Missouri, Columbia is home to the second of the world's largest Spirovent® combination air eliminator and dirt separator.Healthcare Gallery

Spirovent® and Spirotrap® separators are installed in hundreds of hospital and medical centers throughout North America.Boehringer Ingelheim - St. Joseph, MO

Custom 20" high velocity dirt and sediment separator with removable top head for access to Spirotube® element bundle.Higher-Ed Gallery

For almost two decades Spirotherm® has been working with facilities departments to provide solutions for problem systems.Related Work

Purdue University - West Lafayette, IN

Spirovent exceeds expectations and leads the University to purchase and install (32) additional units at the village.Maine Medical Center - Augusta, ME

Three of the larger Spirotherm® products on this multi-system project.International ALERT Academy, Big Sandy, TX

“I have not had to vent a coil in the three months since